Your Ideal Fiber Cable Partner

contact us- Customized Fiber Optic Cable

- Mini Sc Waterproof Patch Cord

- FTTH Fiber Optical Cable

- Outdoor fiber optic cable

- Indoor distribution cable

- Active Optical Cable

- MPO/ MTP Patch Cord

- Field Tactical Cable

- Patch cord/ pigtail

- Fiber Optic Terminal Box

- Fiber Optic Fast Connector

- Fiber Optic Splitter

- Fiber Optic Fusion Splicer

- Fiber Media Converter

- SFP Transceiver

- Fiber Optic Connector Series

- Fiber Optic Patch Panel

- Optical Multimeter

- Optical Fiber Cleaver

- Fiber Optical Accessories

- GPON EPON ONU

Air Blown Fiber Unit (ABF) Fiber Units/Bundles-FU

Features and Benefits(Air Blown Fiber Unit)

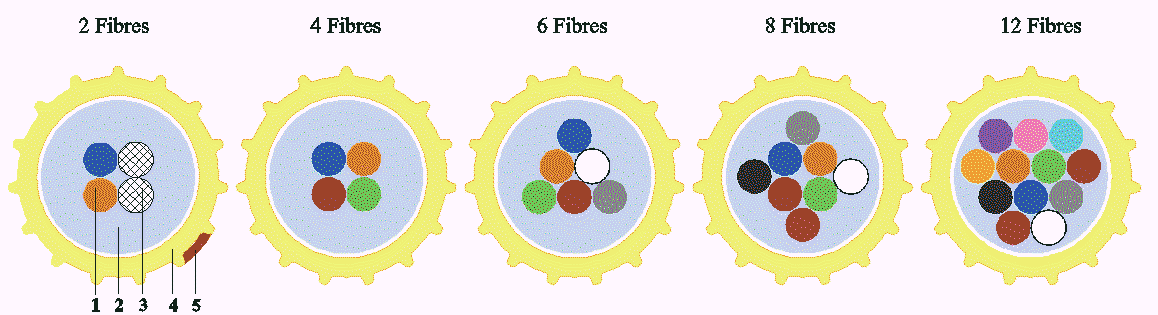

1. 2、4、6、8 and 12 fibres options.

2. Stable structure, good mechanical and temperature performance.

3. Designed with special grooves to advance blowing distance

4. Lightweight and properstiffness ,repeat installation.

5. Designed with no gel, easy stripping and handling.

6. Better costs advantage compared to traditional product.

7. Complete accessories, less manpower, lower installation time.

Technical Parameter

Fibre Unit Structure

• Basic Performance

|

Fibre Count

|

2 Fibres

|

4 Fibres | 6 Fibres |

8 Fibres

|

12 Fibres

|

|

Outer Diameter(mm)

|

1.15±0.05

|

1.15±0.05 | 1.35±0.05 |

1.50±0.05

|

1.65±0.05

|

|

Weight(g/m)

|

1.0

|

1.0 | 1.3 |

1.8

|

2.2

|

|

Min Bend radius(mm)

|

Dynamic: 20 times of cable diameter; Static: 10 times of cable diameter

|

||||

Temperature | Storage:-30℃ ~ +70℃ Operation:-30℃ ~ +70℃ Installation:-5℃ ~ +50℃ | ||||

Cable service life (estimate value) | 25 years | ||||

Note: It is recommended that the structure of 2 fibres unit consist of 2 filled fibres, for it is proved that 2 fibres unit with 2filled fibres is better than the one with zero or one filled fibre in the blowing performance and the fibre stripping-ability | |||||

• Blowing Test

|

Fibre Count

|

2 Fibres

|

4 Fibres | 6 Fibres |

8 Fibres

|

12 Fibres

|

|

Test equipment

|

PLUMETTAZ:UM25,

|

ERICSSON:F, |

CATWAY:FBT-1.1

|

||

|

Standard duct

|

5.0/3.5 mm

|

||||

|

Pressure

|

7bar / 10bar |

||||

Typical blowing distance | 500m/1000m | 500m/1000m | 500m/1000m | 500m/1000m | 500m/800m |

Typical blowing time | 10 min / 18 min | 10 min / 18 min | 12 min / 18 min | 13 min / 18 min | 15 min / 20 min |

• Mechanical Performance

|

Test

|

Standard

|

Parameters

|

Test Results

|

Tension | EN 18700 A1/501

IEC 60794-1-2-E1 | Load is 1xW | Additional attenuation ::0.05dB after test |

|

Bend

|

IEC 60794-1-2--E11A

|

Diam 40mmx3turns 5 cycles at 20C |

Additional attenuation ::0.05dB after test

|

|

Crush

|

IEC 60794-1-2-E3

|

100 N, 60s

|

Additional attenuation ::0.05dB after test

|

|

All optical testing proceeded at 1550 nm

|

|||

• Environment Performance

|

Test

|

Standard

|

Parameters

|

Test Results

|

Temperature Cycle | IEC 60794-1-2-F1 | -300C, +700C,

(2 cycles) | Absolute attenuation ::0.5dB/km,during test

Additional attenuation ::0.1dB/km, during and aftertest |

|

Water Soak

|

IEC 60794-5

|

1000 hours in water, 18℃~22℃ |

(Test after temp cycle) ::0.07dB/km

Change compared to start value |

|

Damp Heat Cycle

|

IEC 60068-2-38

|

250C, 650C, 250C,650C,

250C,-100C, 250C |

Absolute attenuation ::0.5dB/km,during test

Additional attenuation ::0.1dB/km, during and aftertest |

|

All optical testing proceeded at 1550 nm

|

|||

- Tel

- *Title

- *Content