Your Ideal Fiber Cable Partner

contact us- Customized Fiber Optic Cable

- Mini Sc Waterproof Patch Cord

- FTTH Fiber Optical Cable

- Outdoor fiber optic cable

- Indoor distribution cable

- Active Optical Cable

- MPO/ MTP Patch Cord

- Field Tactical Cable

- Patch cord/ pigtail

- Fiber Optic Terminal Box

- Fiber Optic Fast Connector

- Fiber Optic Splitter

- Fiber Optic Fusion Splicer

- Fiber Media Converter

- SFP Transceiver

- Fiber Optic Connector Series

- Fiber Optic Patch Panel

- Optical Multimeter

- Optical Fiber Cleaver

- Fiber Optical Accessories

- GPON EPON ONU

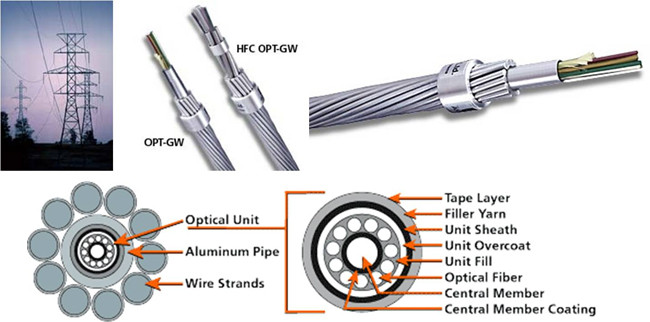

OPGW (Optical Fiber Composite Overhead Ground Wire) 6~288 core

OPGW is a dual functioning cable performing theduties of a ground wire and also providing a patch for the transmission ofvoice, video or data signal. The fibers are protected from environmentalconditions (lightning, short circuit, loading) to ensure reliability andlongevity. The cable is designed to be installed on transmission anddistribution lines to carry voice, data and video communications, especially inlighting waveform monitoring system, an observation system for overhead testline, maintenance data information system, power line protection system, powerline operation system, and unmanned substation monitoring.

OPGW cable, also known as optical fibercomposite overhead ground wire, OPGW cable type generally use aluminum,aluminum frame type and (stainless) steel structure. OPGW cable 250μm fiberstructure is made of stainless steel set into the casing, the casing around thetwisted aluminum clad steel wire (ACS line), the outer wrap aluminum wire (AALine) layer of the mountain cable.

OPGW cable has two constructions:

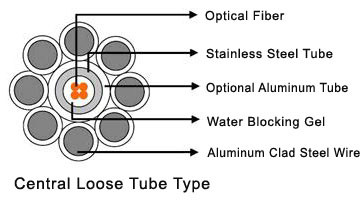

Central loose tube type

The fiber is placed loosely in a sealed and waterresistant stainless steel tube filled with water blocking gel. This tubeprovides protection to the fiber during installation and operation under severeenvironmental conditions. Aluminum layer over the tube is optional. Thestainless optical tube is located at the center of the cable protected bysingle or multiple layers of aluminum clad steel and aluminum annoy wires. Thealuminum clad steel wires are shaped trapezoidally around the optical unit toprovide compact construction. The metallic wires provide mechanical strength towithstand severe installation and operating conditions, while achievingconductivity to control temperature rise during short circuit conditions

This type can accommodate up to 48 fibers in acable. Despite such a high fiber count in a single tube, each optical fiber isclearly distinguishable utilizing a fiber identification system consisting ofcoloring and the number of ring marks on it. This compact design features highmechanical strength and fault current rating within a smaller diameter. Thesmaller diameter also results in excellent sag tension performance

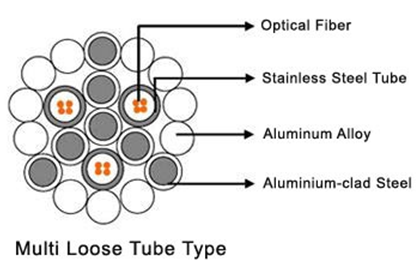

Multi loose tube type

The fiber is placed loosely in a sealed andwater resistant stainless steel tube filled with water blocking gel. Two orthree stainless steel optical tubes are helically stranded in the inner layerof a multiple-layer cable

The multi loose tube type is designed mostly forvery high fiber count requirement over 48 with the maximum fiber count reaching144. The multi loose tube type can meet the requirement of huge cross and largecurrent capacity

Feature of OPGW:

1. Seal stainless steel tube superior protectionto the fiber optical to moisture and extreme environmental conditions such aslightening

2. High pressure over 110kv line, span large(generally in the 250M or more);

3. Easy to maintain, easy to solve problemsacross the line, their mechanical properties can meet the line big leap;

4. OPGW outer layer of metal armor, no effect onthe high-voltage erosion and degradation;

5. The use of advanced production technology ofstainless steel pipe, tube filled with water blocking compound, can effectivelyprotect the optical fiber;

6. Cable diameter and weight approximate withanother ground wire. Less additional load to tower, high tensile strength.

Characteristics of OPGW:

Bio-function of ground wire and communicationcable, avoid a huge expenditure to re-erect and re-maintain;

Erect on top of power overhead line pole, neednot to consider its best hanging point, electro-corrosion, and others.

In the process of old line transformation,cable’s outer diameter and tension may be matched better than another groundwire;

Big transmission capacity, good and reliablecommunication; excellent mechanical and electrical property; Good security,long lifetime.

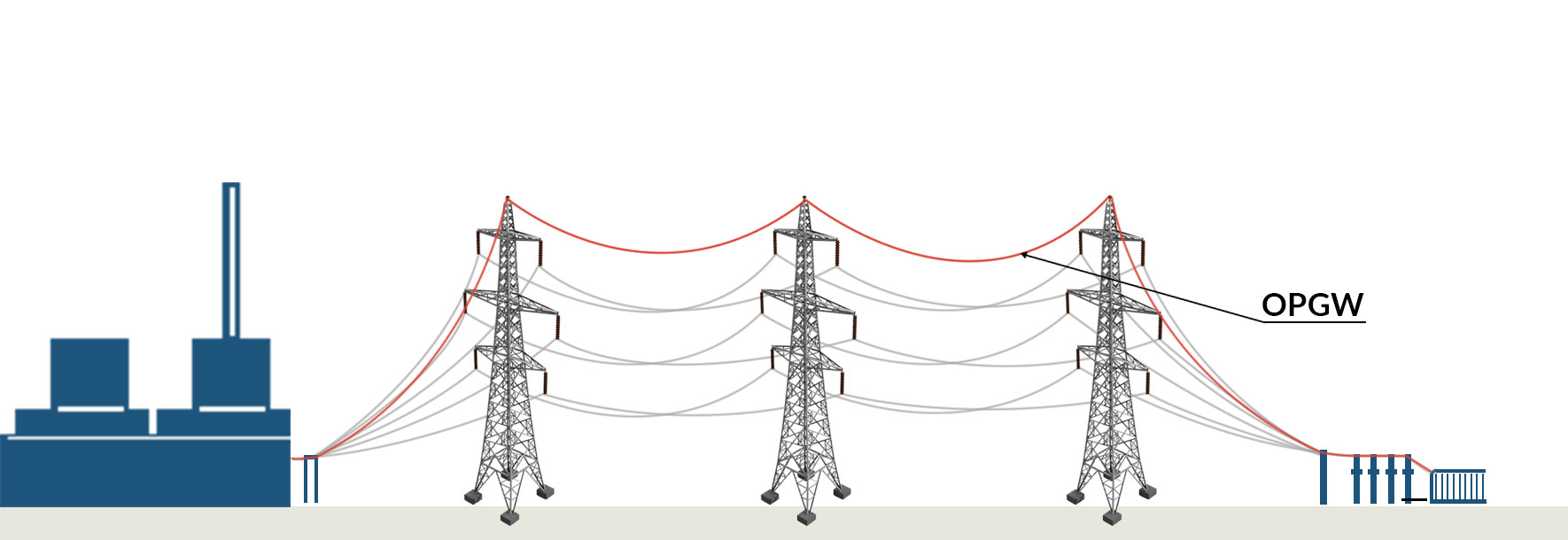

Application of OPGW:

The optical fiber composite ground wire [OPGW]is suitable for installation on new power lines with double function of groundwire and communication, especially for installation on normal voltage and extrahigh voltage power lines.

OPGW can replace conventional ground wire of oldpower line with increasing fiber communication function. They conduct shortcircuit current and provide lightning resistance.

Mechanical Properties

Minimum Bending Radius:

Under installation: 20×OD

During operation: 10×OD for unarmored cables; 20×OD for armoredcables.

Temperature Range:

Operating Temperature Range: -40℃(-40℉) to +70℃(+158℉)

Storage Temperature Range: -50℃(-58℉) to +70℃(+158℉)

Maximum Compressive Load:

4000N for unarmored cables;

6000N for armored cables

Crush Resistance: 220N/cm(125lb/in)

- Tel

- *Title

- *Content